There's an old African proverb that says "If you want to go quickly, go alone. If you want to go far, go together." We have to go far — quickly. And that means we have to quickly find a way to change the world's consciousness about exactly what we're facing, and why we have to work to solve it.

~ Al Gore (winner of the Nobel Peace Prize of 2007)

Digital Ecologic-footprints

compares human demand with ecological capacity to regenerate. Leave nothing but traces in digital world.

Friday, March 18, 2011

Insitu Uranium Mining

Insitu Uranium Leach Mining

In Situ Leach Mining

What is ISL and How long has it been used?

ISL Uranium Deposit Characteristics

ISL Wellfield -an overview

Uranium Recovery

ISL in Australia

Environment & Health

sources

In Situ Leach Mining

Most uranium mining in USA is now by in situ leach (ISL) methods. In USA it is seen as the most cost effective and environmentally acceptable method of mining. There are two proposals well advanced for ISL mining of uranium in Australia.

Conventional mining involves removing rock from the ground, breaking it up and treating it to remove the minerals being sought.

What is ISL and How long has it been used? In situ leaching (ISL), also known as solution mining, involves leaving the ore where it is in the ground, and using liquids which are pumped through it to recover the minerals out of the ore by leaching. Consequently there is little surface disturbance and no tailings or waste rock generated. However, the orebody needs to be permeable to the liquids used, and located so that they do not contaminate ground water away from the orebody.

ISL mining was first tried on an experimental basis in Wyoming during the early 1960s. The first commercial mine began operating in 1974. Today about a dozen projects are licensed to operate in the USA, (in Wyoming, Nebraska and Texas) and most of the operating mines are less than 10 years old. Most are small, by Australian standards but they supply some 85% of the US uranium production. About 13% of world uranium production is by ISL (including all Kazakhstan and Uzbekistan output).

ISL can also be applied to other minerals such as copper and gold.

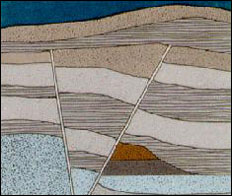

ISL Uranium Deposit Characteristics Uranium deposits suitable for ISL occur in permeable sand or sandstones, confined above and below by impermeable strata and below the water table. They may either be flat, or "roll front",- in cross section, C-shaped deposits within a permeable sedimentary layer.

They were formed by the lateral movement of groundwater bearing oxidised uranium minerals through the aquifer, with precipitation of the minerals occurring when the oxygen content decreased, along extensive oxidation-reduction interfaces. The uranium minerals are usually uraninite (oxide) or coffinite (silicate) coatings on individual sand grains. The ISL process essentially reverses this ore genesis, in a much shorter time frame.

Techniques for ISL have evolved to the point where it is a controllable, safe, and environmentally benign method of mining which can operate under strict environmental controls and which often has cost advantages.

ISL Wellfield -an overview Wells are cased to ensure that liquors only flow to and from the ore zone. Submersible electric pumps draw from near the bottom of the production wells.

A wellfield design is typically a grid with alternating production and injection wells. The spacing between them usually ranges from 15 to 30 metres. A series of monitor wells are situated around the whole wellfield to ensure that contaminated water does not move outside the mining area.

Oxygen is injected into the leach liquors as they are returned to the injection wells and drawn into the ore zone to oxidise the uranium minerals. They are then removed as the liquors are pumped out.

While uranium production in Australia uses acid leaching of the crushed ore, ISL overseas normally uses alkaline leaching agents such as a combination of sodium bicarbonate and carbon dioxide. At Honeymoon in SA, the process will be acid leaching with weak sulfuric acid plus oxygen. The leaching solution is at a pH of 2.8 - 2.0, about the same as vinegar.

In USA the production life of an individual ISL wellfield is usually less than 3 years, typically 6-10 months. Most of the uranium is recovered during the first 6 months of the wellfield's operation. The most successful operations have achieved a total overall recovery of about 80% of the ore. Over time, production flows decrease as clay and silt become trapped in the permeable sediments. These can be dislodged to some extent by using higher-pressure injection or by reversing the flow between injection and production wells.

Uranium Recovery The pregnant solution from the production wells is pumped to the treatment plant where the uranium is removed from it in an ion exchange system; or by solvent extraction. The uranium is then stripped from the ion exchange resin, and precipitated chemically.

Most of the solution is returned to the injection wells, but a little is bled off and treated as wastewater. It contains various dissolved minerals such as radium, arsenic and iron. Barium chloride is added to precipitate the radium. This bleed of process solution ensures that there is a steady flow into the wellfield from the surrounding aquifer, rather than having any leach liquor move in the other direction. Before the process solution is reinjected, it is oxygenated and if necessary recharged with sodium bicarbonate or acid.

ISL in Australia Two projects are currently proposed for ISL mining operations in Australia; Honeymoon and Beverley, both in the Lake Frome area of South Australia between Broken Hill and the northern Flinders Ranges.

At Honeymoon the uranium deposit occurs in porous sandstone at a depth of 100 to 120 metres and extending over about 24 hectares of a buried riverbed (palaeochannel).

Honeymoon was discovered in 1972, about 75 kilometres north west of Broken Hill. Early in 1997 Sedimentary Holdings NL reached agreement with MIM Holdings Ltd to acquire the Honeymoon and two adjacent uranium deposits next to its own Chatfield (East Kalkaroo) deposits.

This brings together uranium resources of about 6800 tonnes U3O8 averaging 0.15% and amenable to ISL. The purchase was funded by Southern Cross Resources Inc. of Toronto which raised funds in Canada for the development of the SA uranium properties. Sedimentary Resources (an Australian company) holds 35% of Southern Cross.

Plans had been developed in the 1970s to extract the uranium oxide by ISL, and some $12 million was spent in preparation then. Draft and Final Environmental Impact Statements were produced, and both South Australian and Commonwealth environmental approval was subsequently obtained in 1981 for production to 450 t/yr. Field tests of the in situ leaching process were carried out and a $3.5 million, 110 t/yr pilot plant was built and remains on site, but the project was abandoned in 1983*.

Southern Cross now plans to bring Honeymoon and the associated deposits into production in 1998, building up to 450 tonnes per year by 2000.

The Beverley deposit, 520 kilometres north of Adelaide is northwest of Honeymoon and geologically similar to it. Plans to mine it by ISL were abandoned in 1983 when the South Australian Government refused to grant permission for development to proceed*. The deposit was sold to Heathgate Resources Pty Ltd, an affiliate of General Atomics of USA, in 1990.

Three ore lenses lie at a depth of 110-140 metres, over some 4 km. Their 6 million tonnes of 0.27% ore contains 16 200 tonnes of uranium oxide. An estimated 11 500 tonnes of this was considered recoverable by ISL at 900 tonnes per year, making it the largest Australian deposit of its kind.

Hydrogeological tests and operation of a continuous field leach trial are being undertaken in 1997-98, along with preparation of a new Environmental Impact Statement. Heathgate Resources is working towards commencing production before 2000.

Environment & Health At established operations overseas, after ISL mining is completed, the quality of the remaining groundwater must be restored to a baseline standard determined before the start of the operation, so that any prior use can be resumed. Contaminated water drawn from the aquifer is either evaporated or treated before reinjection.

In contrast to the main US operations, the water quality at the Australian sites is very low to start with, and it is quite unusable. At Beverley the groundwater in the orebody is very saline and orders of magnitude too high in radionuclides for any permitted use. At Honeymoon the water is similarly very saline, and high in sulfates and radium. When acid leaching is discontinued, the water quality reverts to its original condition.

Upon decommissioning, wells are sealed or capped, process facilities removed, any evaporation pond revegetated, and the land can readily revert to its previous uses.

The usual radiation safeguards are applied at an ISL mining operation, despite the fact that most of the orebody's radioactivity remains well underground and there is hence no increase in radon release and no ore dust. Employees are monitored for alpha radiation contamination and personal dosimeters are worn to measure exposure to gamma radiation. Routine monitoring of air, dust and surface contamination are undertaken.

- due to the ALP "3 mines" policy

Information Administration, Uranium Industry Annual. Uranium Institute, 1996, Global Nuclear Fuel Market,supply & demand 1995-2015.

Solar Energy

http://earthsci.org/mineral/energy/solar/solar.html

Photovoltaic Systems

Movement of Light

Solar Cell Materials

Turning Sunlight into Energy

From Cells to Arrays

Cells to Arrays - a closer look

PV Cells with Battery Storage

How does a cell produce electricity?

Glossary of PV Terms

Photovoltaic (or PV) systems convert light energy into electricity. The term "photo" is a stem from the Greek "phos," which means "light." "Volt"is named for Alessandro Volta (1745-1827), a pioneer in the study of electricity. "Photo-voltaics," then, could literally mean "light-electricity. Most commonly known as "solar cells," PV systems are already animportant part of our lives. The simplest systems power many of the small calculators and wrist watches we use every day. More complicated systems provide electricity for pumping water, powering communications equipment, and even lighting our homes and running our appliances. In asurprising number of cases, PV power is the cheapest form of electricity for performing these tasks.

Here, we describe the PV effect that allows various materials to produce electricity from sunlight; show how PV cells, modules, and arrays are made; explain why PV is the most logical power choice in many different cases; and provide real examples of how this science is improving the lives of people all over the world!

Movement of Light

The movement of light from one location to another can best be describedas though it were a wave, and different types of radiation are characterizedby their individual wavelengths (a wavelength is the distance from the peakof one wave to the peak of the next). These wavelengths indicate radiationwith different amounts of energy; the longer the wavelength, the less the energy. Red light, then, has a longer wavelength and thus has less energythan violet light.

Each second, the sun releases an enormous amount of radiant energy intothe solar system. The Earth receives a tiny fraction of this energy; still, anaverage of 1367 watts (W) reaches each square meter (m2) of the outeredge of the Earth's atmosphere. The atmosphere absorbs and reflects some of this radiation, including most X-rays and ultraviolet rays. Still, the amount of sunshine energy that hits the surface of the Earth every minute is greater than the total amount of energy that the world's human population consumes.

The most important parts of a solar cell are the semiconductor layers, because this is where the electron current is created. There are a number of different materials suitable for making these semiconducting layers, and each has benefits and drawbacks. Unfortunately, there is no one ideal material for all types of cells and applications. In addition to the semiconducting materials, solar cells consist of a top metallic grid or other electrical contact to collect electrons from the semiconductor and transfer them to the external load, and a back contactlayer to complete the electrical circuit. Then, on top of the complete cell is typically a glass cover or other type of transparent encapsulant to seal the cell and keep weather out, and an anti reflective coating to keep the cell from reflecting the light back away from the cell.

A typical solar cell consists of a cover glass or other encapsulant, an anti-reflective layer, a front contact to allow the electrons to enter a circuit and a back contact to

allow them to complete thecircuit, and the semiconductor layers where the electrons begin and complete their voyages.

Here are some substances commonly used in solar cells:

Silicon

Silicon is still the most popular solar cell material for commercial applications because it is so readily abundant (it is actually the second most abundant element in the Earth's crust second only to oxygen!). However, to be useful in solar cells, it must be refined to 99.9999% purity.

In single-crystal silicon, the molecular structure of the material is uniform because the entire structure is grown from the same or a "single" crystal. This uniformity is ideal for efficiently transferring electrons through the material. To make an effective PV cell, silicon is "doped" to make it n-type and p-type. Semicrystalline silicon, on the other hand, consists of several smaller crystals or "grains," which introduce "boundaries." These boundaries impede the flow of electrons and encourage them to recombine with holes and thereby reduce the power output of the cell. However, semicrystalline silicon is much cheaper to produce than single-crystalline silicon, so researchers are working on other ways of minimizing the effects of grain boundaries.

Gallium Arsenide

Gallium arsenide (GaAs) is a compound semiconductor: a mixture of two elements, gallium (Ga) and arsenic (As). Gallium is a byproduct of the smelting of other metals, notably aluminum and zinc, and it is rarer than gold. Arsenic is not rare, but it is poisonous. Gallium arsenide's use in solar cells has been developing synergistically with its use in light-emitting diodes, lasers, and other opto-electronic devices.

GaAs is especially suitable for use in multijunction and high-efficiency solar cells for several reasons:

1. The GaAs band gap is 1.43 eV, nearly ideal for single-junction solar cells.

2. GaAs has an absorbtivity so high it requires a cell only a few microns thick to absorb sunlight. (Crystalline silicon requires a layer 100 microns or more in thickness.)

3. Unlike silicon cells, GaAs cells are relatively insensitive to heat. (Cell temperatures can often be quite high, especially in concentrator applications.)

4. Alloys made from GaAs using aluminum, phosphorus, antimony, or indium have characteristics complementary to those of gallium arsenide, allowing great flexibility in cell design.

5. GaAs is very resistant to radiation damage. This, along with its high efficiency, makes GaAs very desirable for space applications.

One of the greatest advantages of gallium arsenide and its alloys as PV cell materials is the wide range of design options possible. A cell with a GaAs base can have several layers of slightly different compositions that allow a cell designer to precisely control the generation and collection of electrons and holes. (To accomplish the same thing, silicon cells have been limited to variations in the level of doping.) This degree of control allows cell designers to push efficiencies closer and closer to theoretical levels. For example, one of the most common GaAs cell structures uses a very thin window layer of aluminum gallium arsenide. This thin layer allows electrons and holes to be created close to the electric field at the junction.

Polycrystalline Thin Films

One of the scientific discoveries of the computer semiconductor industry that has shown great potential for the PV industry is thin film technology. Polycrystalline thin film devices require very little semiconductor material and have the added advantage of being easy to manufacture. Rather than growing, slicing, and treating a crystalline ingot (required for single-crystal silicon), we sequentially deposit thin layers of the required materials.

Several different deposition techniques are available, and all of them are potentially cheaper than the ingot growth techniques required for crystalline silicon. Best of all, these deposition processes can be scaled uneasily so that the same technique used to make a 2-inch x 2-inch laboratory cell can be used to make a 2-foot x 5-foot module (in a sense, a huge cell!). Like amorphous silicon, the layers can be deposited on various low-cost substrates (actually "superstrates," see Transparent Conductors)

like glass or plastic in virtually any shape -- even flexible plastic sheets.

Single-crystal cells have to be individually interconnected into a module, but thin film devices can be made monolithically (as a single unit). Layer upon layer is deposited sequentially on a glass superstrate, from the antireflection coating and conducting oxide, to the semiconductor materialand the back electrical contacts.

Polycrystalline Thin Films:

Cell Structure

Unlike most single-crystal cells, the typical thin film device does not use a metal grid for the top electrical contact. Instead, it uses a thin layer of a transparent conducting oxide (such as tin oxide). These oxides are highly transparent and conduct electricity very well. A separate antireflection coating may be used to top off the device, or the transparent conducting oxide may serve this function as well.

Polycrystalline thin film cells comprise many tiny crystalline grains of semiconductor materials. The materials used in polycrystalline thin-film cells have properties that are different from those of silicon, so it has proven to be better to create the electric field with an interface between two different semiconductor materials. This type of interface is called a heterojunction ("hetero" because it is formed from two different materials,

in comparison to the "homojunction" formed by two doped layers of the same material, such as the one in silicon solar cells).

Turning Sunlight into Energy

About Conversion Efficiencies

The conversion efficiency of a PV cell is the proportion of sunlight energythat the cell converts to electrical energy. This is very important whendiscussing PV devices, because improving this efficiency is vital to makingPV energy competitive with more traditional sources of energy (e.g., fossilfuels). Naturally, if one efficient solar panel can provide as much energy as two less efficient panels, then the cost of that energy (not to mention the space required) will be reduced. For comparison, the earliest PV devicesconverted about 1%-2% of sunlight energy into electric energy. Today'sPV devices convert 7%-17% of light energy into electric energy.Of course, the other side of the equation is the money it costs to manufacture the PV devices. This has been improved over the years aswell. In fact, today's PV systems produce electricity at a fraction of thecost of early PV systems.

AC and DC Current

PV modules, because of their electrical properties, produce direct ratherthan alternating current (ac). Direct current (dc) is electric current thatflows in a single direction. Many simple devices, such as those that run onbatteries, use direct current. Alternating current, in contrast, is electriccurrent that reverses its flow direction at regular intervals. This is the typeof electricity provided by utilities and is required to run most modern appliances and electronic devices.

In the simplest systems, dc current produced by PV modules is useddirectly. In applications where ac current is necessary, an inverter can beadded to the system to convert the dc current to ac current.

Turning Sunlight Into Electricity

Light and the Sun

The sun's energy is vital to life on Earth. It determines the Earth's surfacetemperature and supplies virtually all the energy that drives natural globalsystems and cycles. Although some other stars are enormous sources ofenergy in the form of X-rays and radio signals, our sun releases 95% of itsenergy as visible light. Yet, visible light represents only a fraction of thetotal radiation spectrum; infrared and ultraviolet rays are also significantparts of the solar spectrum.

frequency and the greater the

energy (expressed in eV, or electron volts).

Each portion of the solar spectrum is associated with a different level ofenergy. Within the visible portion of the spectrum, for example, red light isat the low-energy end and violet light is at the high-energy end (having halfagain as much energy as red light). In the invisible portions of thespectrum, photons in the ultraviolet region, which cause the skin to tan,have more energy than those in the visible region. Likewise, photons in theinfrared region, which we feel as heat, have less energy than the photonsin the visible region.

The "photovoltaic effect" is the basic physical process through which a PVcell converts sunlight into electricity. Sunlight is composed of photons, orparticles of solar energy. These photons contain various amounts ofenergy corresponding to the different wavelengths of the solar spectrum (see "Light and the Sun" for more about that). When photons strike a PVcell, they may be reflected or absorbed, or they may pass right through.

Only the absorbed photons generate electricity. When this happens, theenergy of the photon is transferred to an electron in an atom of the cell(which is actually a semiconductor). With its newfound energy, the electron is able to escape from its normal position associated with thatatom to become part of the current in an electrical circuit. By leaving thisposition, the electron causes a "hole" to form. Special electrical propertiesof the PV cell-a built-in electric field provide the voltage needed to drive

the current through an external load (such as a light bulb).

p-Types, n-Types, and the Electric Field

To induce the electric field within a PV cell, two separate semiconductorsare sandwiched together. The "p" and "n" types of semiconductorscorrespond to "positive" and "negative" because of their abundance ofholes or electrons (the extra electrons make an "n" type because an electron actually has a negative charge).

Although both materials are electrically neutral, n-type silicon has excess electrons and p-type silicon has excess holes. Sandwiching these togethercreates a p/n junction at their interface, thereby creating an electric field. When the p-type and n-type semiconductors are sandwiched together, theexcess electrons in the n-type material flow to the p-type, and the holes

thereby vacated during this process flow to the n-type. (The concept of a hole moving is somewhat like looking at a bubble in a liquid. Although it's the liquid that is actually moving, it'seasier to describe the motion of thebubble as it moves in the opposite direction.) Through this electron andhole flow, the two semiconductors act as a battery, creating an electricfield at the surface where they meet (known as the "junction"). It's this

field that causes the electrons to jump from the semiconductor out toward the surface and make them available for the electrical circuit. At this sametime, the holes move in the opposite direction, toward the positive surface, where they await incoming electrons.

From Cells to Arrays

The PV cell is the basic unit in a PV system. An individual PV cell typicallyproduces between 1 and 2 watts, hardly enough power for the greatmajority of applications. But we can increase the power by connectingcells together to form larger units called modules. Modules, in turn, can beconnected to form even larger units known as arrays, which can be interconnected for more power, and so on. In this way, we can build a PVsystem to meet almost any power need, no matter how small or great.

Modules or arrays, by themselves, do not constitute a PV system. We must also have structures on which to put them and point them toward thesun, and components that take the direct current (dc) electricity producedby the modules or arrays and condition the electricity so it can be used inthe specific application. These structures and components are referred toas the balance of system (BOS).

When sunlight strikes a solar cell, only certain bands (or wavelengths)of light will cause electrons to move within the semiconductor, therebyproducing electric current. The energy "band gap" of thesemiconductor determines the ideal portion of the light spectrum that will create this effect. To allow it all to happen, the semiconductorlayers must be constructed so as to produce an electric fieldThe wavelengths of light above the cell's band gap (left) carry more energy. Some of this energy is absorbed to free electrons in the cell,and some of it is absorbed as heat. Light energy below the cell's band gap

(right) passes right through the field without affecting electron movement. Overall, only abut 55% of the sun's light energycan be converted into electricity.

So, the typical solar cell receives the entire solar spectrum. But onlythe light energy above the cell's energy gap

will cause electrons to move and become part of an electric circuit.

Cells to Arrays

The solar cell is the basic building block of a PV system. Individual cells can vary in size from about 1 cm (1/2 in.) to about 10 cm (4 in.) across. However, one cell only produces 1-2 W, which isn't enough power for most applications

(Photo: Siemens Solar Industries)

A module typically consists of several solar cells, although thin-film materials like amorphous silicon and cadmium

telluride can be made directly into modules, effectively bypassing the solar cell. These two silicon modules are rated at approximately 50 W each and provide power for a street light using 12 V battery storage.

Modules such as these can also be connected into arrays for more power.

(Photo: W. Gretz, NREL)

Arrays are the large power producers and consist of several modules. They can be used to provide up to several megawatts of electric power.

The basic photovoltaic cell typically produces only a small amount of power. To produce more power, cells can be interconnected to form modules, which can in turn be connected into arrays to produce yet more power. Because of this modularity, PV systems may be designed to meet any electrical requirement, no matter how large or how small.

PV Cells with Battery Storage

PV systems with batteries operate by connecting the PV modules to abattery, and the battery, in turn, to the load. During daylight hours, the PVmodules charge the battery. The battery supplies power to the loadwhenever needed. A simple electrical device called a charge controllerkeeps the batteries charged properly and helps prolong their life by protecting them from overcharging or from being completely drained. Batteries make PV systems useful in more situations, but also require somemaintenance. The batteries used in PV systems are often similar to carbatteries, but are built somewhat differently to allow more of their storedenergy to be used each day. (They are said to be "deep cycling," like thebatteries used on golf carts.) Batteries designed for PV projects pose thesame risks and demand the same caution in handling and storage as automotive batteries. The fluid in unsealed batteries should be checkedperiodically, and batteries should be protected from extremely cold weather.

A solar generating system with batteries supplies electricity when it isneeded. How much electricity can be used after sunset or on cloudy daysis determined by the output of the PV modules and the nature of thebattery bank. Including more modules and batteries increases system cost, so energy usage is carefully studied to determine optimum system size. Awell designed system balances cost and convenience to meet the user'sneeds, and can be expanded if those needs change.

How does a cell produce electricity?

A typical solar cell is made from a substance called silicon. Silicon is known as a semiconductor. A semiconductor is neither a good insulator nor a good insulator; it falls somewhere in between. A solar cell is constructed with silicon that has been altered to form two different types of semiconductor material. These two different types of silicon are then joined in such a way as to form a junction.

Due to the different types of semiconductor material that make up this junction, a permanent electric field is forced to appear in this region. When a photon from a light source such as the sun strikes the cell, it causes an electron in the semiconductor material to jump to a higher orbit and jump from atom to atom. The permanent electric field forces the electron to move only in a particular direction, out of the cell and through a circuit such as a light bulb, a motor or battery etc. and then back to the other side of the junction thus performing work.

By connecting cells together to form a solar panel we can do even more work. The typical individual silicon solar cell has the potential of generating about half a volt, but by wiring them in series or end to end you can increase the voltage. In other words, 36 individual cell will produce about 18 volts. The size of the individual cell is what determines the amount of current of amps that a solar panel can produce.

Glossary of PV Terms

This brief glossary is offered as a basic guideline. Click on any term to receive the definition, then click on the term again to return here.

AC

Ampere

Ampere Hour

Ampere Hour Meter

Angle Of Incidence

Array

Balance Of System

Battery

Battery Capacity

Battery Cell

Battery Available Capacity

Battery Energy Capacity

Battery Cycle Life

Battery Life

Blocking Diode

Cathodic Protection

Cell (Battery)

Cell (Solar)

Charge Rate

Charge Controller

Concentrator

DC

Depth Of Discharge

Diffuse Insolation

Direct Insolation

Efficiency

Electrolyte

Electric Current

Electricity Energy

Electrons

Equalization

Equalizing Charge

Float Service

Full Sun

Gassing

Grid

Grid Lines

Hermetic Seal

Hybrid System

Incident Light

Insolation

Inverter

Kilowatt-Hour (Comparison Of Fuel Equivalents)

Load

Maximum Power

Module

Open Circuit Voltage

Panel

Parallel Connection

Peak Power Point

Peak Watts

Photon

Photovoltaic Cell

Photovoltaic Effect

Photovoltaic System

Power Conditioner

Power Factor

Regulator

Renewable Energy

Semiconductor

Series Connection

Silicon

Single-Crystal Structure

Solar Cell

Solar Panel

Stand-Alone System

Storage Battery

Sulfation

Telemetry Device

Tilt Angle

Tracking Array

Voltage

Watt

AC: Alternating Current. Direction of current reverses periodically, usually many times per second. Electricity transmission networks use AC because voltage can be controlled with relative ease.

Ampere (amp): A unit of electrical current or rate of flow of electrons. One volt across one ohm of resistance causes a current flow of one ampere. One ampere is equal to 6.235 x 1018 electrons per second passing a given point in a circuit.

Ampere hour: (amp hr. Or ah), a measure of current overtime, used to measure battery capacity.

Ampere hour meter: An instrument that monitors current

with time. The indication is the product of current (in amperes) and time (in hours).

Angle of Incidence: The angle between the direct solar beam and the normal (90 degrees) to the active surface (degrees).

Array: Any number of photovoltaic modules connected together electrically to provide a single electrical output. An array is a mechanically integrated assembly of modules or panels together with support structure (including foundation and other components, as required) to form a free- standing field installed unit that produces DC power.

Balance of systems (bos): Parts or components of a photovoltaic system other than the photovoltaic array.

Battery: Two or more electrochemical cells enclosed in

a container and electrically interconnected in an appropriate series/parallel arrangement to provide the required operating voltage and current levels. Under common usage, the term battery also applies to a single cell if it constitutes the entire

electrochemical storage system.

Battery capacity: The maximum total electrical charge,expressed in ampere-hours (ah), that a battery can deliver to a load under a specific set of conditions.

Battery cell: The simplest operating unit in a storage

battery. It consists of one or more positive electrodes or plates, an electrolyte that permits ionic conduction, one or more negative electrodes or plates, separators between plates of opposite polarity, and a container for all the above.

Battery available capacity: The total maximum charge, expressed in ampere-hours, that can be withdrawn from a cell or battery under a specific set of operating conditions including discharge rate, temperature, initial state of charge, age, and cutoff voltage.

Battery energy capacity: the total energy available, expressed in watt-hours (kilowatt-hours), that can be withdrawn from a fully-charged cell or battery. The energy capacity of a given cell varies with temperature, rate, age, and cutoff voltage.

This term is more common to system designers than it is to the battery industry where capacity usually refers to ampere-hours..

Battery cycle life: The number of cycles, to a specified depth of discharge, that a cell or battery can undergo before failing to meet its specified capacity or efficiency performance criteria..

Battery life: The period during which a cell or battery

is capable of operating above a specified capacity or efficiency performance level. For example, with lead-acid batteries, end-of- life is generally taken as the point in time when a fully charged cell can deliver only 80% of its rated capacity. Beyond this state of aging, deterioration and loss of capacity begins to accelerate rapidly. Life may be measured in cycles and/or years, depending on the type of service for which the cell or battery is intended.

Blocking diode: A semiconductor connected in series

with a solar cell or cells and a storage battery to keep the battery from discharging through the cell when there is no output, or low output, from the solar cell. It can be thought of as a one-way valve that allows electrons to flow forwards, but not backwards.

Cathodic protection: Systems that protect underground

metal from corrosion by running small electrical currents along the metal. Most often used to protect wellheads, oil, gas, and water pipelines.

Cell (battery): A single unit of an electrochemical device capable of producing direct voltage by converting chemical energy into electrical energy. A battery usually consists of several cells electrically connected together to produce higher voltages. (sometimes the terms cell and battery are used interchangeably).

Cell (solar): The smallest, basic photovoltaic device that generates electricity when exposed to light.

Charge rate: The current applied to a cell or battery to restore its available capacity. This rate is commonly normalized by a charge control device with respect to the rated capacity of the cell or battery.

Charge controller: a component of photovoltaic system that controls the flow of current to and from the battery to protect the batteries from over-charge and over-discharge. The charge controller may also indicate the system operational status.

Concentrator: a photovoltaic module which includes optical components, such as lenses, to direct and concentrate sunlight onto a solar cell of smaller area. Most concentrator arrays must directly face or track the sun.

DC: Direct Current. A one way flow of electric current. Typical sources of direct currents are electric cells, rectified power units and direct current generators. This is the current flow produced by a solar cell system. To be used for typical 120 volt or 220 volt household appliances, it must be converted to AC.

Depth of Discharge (dod): The ampere-hours removed from a fully charged cell or battery, expressed as a percentage of rated capacity. For example, the removal of 25 ampere- hours from a fully charged 100 ampere-hours rated cell results in a 25% depth of discharge. Under certain conditions, such as discharge rates lower than that used to rate the cell, depth of discharge can exceed 100%.

Diffuse insolation: The radiant energy from the sky incident upon unit surface area during a specified time period (same units as for direct insolation).

Direct insolation: The radiant energy from the sun (and a small area of sky surrounding it, defined by the acceptance angle of the pyrheliometer) incident upon unit surface area during a specified time period. (mj/m2 per hour, day, week, month or year, as the case may be).

Efficiency: The ratio of power output of a photovoltaic cell to the incident power from the sun or simulated sun sources under specified standard insolation conditions.

Electrolyte: The fluid used in batteries as the transport medium for positively and negatively charged ions.

Electric current: The rate at which electricity flows

through an electrical conductor, usually measured in amperes (amps).

Electricity energy: Resulting from the flow of charge particles, such as electrons ions.

Electrons: A negatively charged particle. The movement of electrons in an electrical conductor constitutes an electric current.

Equalization: The process of restoring all cells in a battery to an equal state-of-charge. For lead-acid batteries, this is a charging process designed to bring all cells to 100% state- charge. Some battery types may require a complete discharge as a part of the equalization process.

Equalizing charge: A continuation of normal battery charging, at a voltage level slightly higher than the normal end-of-charge voltage, in order to provide cell equalization within a battery.

Float service: A battery operation in which the battery is normally connected to an external current source; for instance, a battery charger which supplies the battery load under normal conditions, while also providing enough energy input to the battery to make up for its internal quiescent losses, thus keeping the battery always up to full power and ready for service.

Full sun: The full sun condition is the amount of power density received at the surface of the earth at noon on a clear day - about 100 mw/cm2. Lower levels of sunlight are often expressed as 0.5 sun or 0.1 sun. A figure of 0.5 sun means that the power density of the sunlight is one-half of that of a full sun.

Gassing: The evolution of gas from one or more of the electrodes in the cells of a battery. Gassing commonly results from local action self-discharge) or from the electrolysis of water in the electrolyte during charging.

Grid: Transmission line network used to distribute electric power.

Grid lines: Metallic contacts fused to the surface of the solar cell to provide a low resistance path for electrons to flow out to the cell interconnect wires.

Hermetic seal: Being impervious to external influences. Typically associated with the sealing of a package so that oxygen, moisture, and other outside environments cannot enter the package.

Hybrid system: a power system consisting of two or more power generating subsystems (e.g., The combination of a wind turbine or diesel generator and a photovoltaic system. The SES Photogenset® is an example of such a system.

Incident light: The incident light is the amount of light reaching an object.

Insolation: The amount of sunlight reaching an area. Usually expressed in milliwatts per square centimeter, or langleys.

Inverter: a device that converts electricity from DC to AC.

Kilowatt-hour unit of energy used to perform work (energy and work are equivalent in units, energy being the potential value and work the achieved value)

Fuel equivalents:

one barrel of crude contains roughly 1700 kwh

one ton of coal contains roughly 7500 kwh

one gallon of gasoline contains roughly 37 kwh

one cubic foot of natural gas contains 0.3 kwh

one ton of uranium ore contains 164 million kwh 1.34

horsepower-hours.

Thermal unit:

one kwh = 3400 btu. Can be compared to 860 calories

(food value)

Example:

The 'average Australian home uses about 20 kwh of

electricity per day. Heating 12Litres of water from 30 degrees to the boiling point requires 1 kwh. A 200 watt photovoltaic array of six, 50 watt solar modules, will generate 1 kwh in an "average" day (annualized average equivalent of 5 hours peak sunlight per day).

Load: Refers to equipment that is powered by electricity. Usually expressed in terms of amperes or watts. In an electrical circuit, any device or appliance that uses power (such as a light bulb or water pump).

Maximum power: The power at the point on the current-voltage characteristic where the product of current and voltage is a maximum (measured in watts).

Module: The smallest non divisible, self-contained and environmentally protected physical structure housing interconnected photovoltaic cells and providing a single DC electrical output.

Open circuit voltage (ocv): Voltage produced by a

photovoltaic cell with noload applied when the cell is exposed to standardinsolation conditions, measured with a voltmeter.

Panel: A collection of one or more modules fastened together into a single unit, often factory pre- assembled and wired, forming a field-installable unit.

Parallel connection: A wiring configuration used to increase current (amperage). Parallel wiring is positive to positive (+ to +) and negative to negative (- to -). Opposite of a series connection.

Peak power point: Operating point of the i-v (current-voltage) curve for a photovoltaic cell or module where the product of the current value times the voltage value is a maximum.

Peak watts: The measurement of electricity produced by a solar generator at noon on a sunny day, under predetermined standard conditions.

Photon: The actual (physical) particle unit of light,

as the electron is of electric charge and the atom and molecule are of matter. Light has both wave properties and particle properties. Violet light has relatively short wavelength and higher energy in its photons; red light has longer wavelength, lower-energyphotons. The wavelength and/or energy spectrum of the sun extends in both directions beyond the visible range of light, of course, and the silicon module solar cell can capture some energy both of these invisible zones. Photons not captured by the cell are either reflected or converted to heat in the solar array.

Photovoltaic cell: A device composed of specially prepared semiconductor material or material combinations exhibiting the ability to convert incident solar energy directly into electrical energy.

Photovoltaic effect: The phenomenon that occurs when photons, the "particles" in a beam of light, knock electrons loose from the atoms they strike. When this property of light is combined with the properties of semiconductors, electrons flow in one direction across a junction, setting up a voltage. With the addition of circuitry, current will flow and electric power will be available.

Photovoltaic system: An installed aggregate of solar

arrays generating power for a given application. A system may include the following sub-systems:

a. support foundation

b. power conditioning and control equipment

c. storage

d. active thermal control

e. land security systems and buildings

f. conduit/wiring

g. instrumentation

Power conditioner: The electrical equipment used to convert power from a photovoltaic array into a form suitable for subsequent use. Loosely, a collective term for inverter, transformer, voltage regulator and other power controls.

Power factor: The ratio of real power (watts) to

apparent power (volt amps) in an AC circuit. Displacement power factor is the ratio of fundamental watts to fundamental RMS volts times RMS amps, excluding the effects of all harmonic exponents; it could be called fundamental power factor.

Regulator: Prevents overcharging of batteries by controlling charge cycle - usually adjustable to conform to specific battery needs.

Renewable energy: Flows of energy that are regenerative or virtually inexhaustible. Most commonly includes solar electric and thermal), biomass, geothermal, wind, tidal, wave, and hydro power sources.

Semiconductor: A material such as silicon, which has a

crystalline structure that will allow current to flow under certain conditions. Semiconductors are usually less conductive than metals but not an insulator like rubber.

Series connection: A wiring configuration used to increase voltage. Series wiring is positive to negative (+ to -) or negative to positive (- to +). Opposite of parallel connection.

Silicon: A non-metallic element, that when specially treated, is sensitive to light and capable of transforming light into electricity. Silicon is the basic material of most beach sand, and is the raw material used to manufacture most photovoltaic cells.

Single-crystal structure: A material having a crystalline structure such that a repeatable or periodic molecular pattern exists in all three dimensions.

Solar cell: The basic photovoltaic device which generates electricity when exposed to sunlight.

Solar panel: A collection of solar modules connected in

series, in parallel, or in series- parallel combination to provide greater voltage, current, or power than can be furnished by a single solar module. Solar panels can be provided to furnish any desired voltage, current, or power. They are made up as a complete assembly. Larger collections of solar panels are usually called

solar arrays.

Stand-alone system: (sos) a system which operates independently of the utility lines. It may draw supplementary power from the utility but is not capable of providing power to the utility.

Storage battery: A device capable of transforming energy from electric to chemical form and vice versa. The reactions are almost completely reversible. During discharge, chemical energy is converted to electric energy and is consumed in an external circuit or apparatus.

Sulfation: The formation of lead sulfate crystals on the plates of a lead-acid battery. Commonly used to indicate the large crystals which form in partially discharged cells as the result of temperature cycling. These large crystals are more difficult to reduce by the charging current than are the smaller crystals that result from normal and self-discharge reactions. Sulfating can be caused by leaving the battery in a discharged state for long periods of time.

Telemetry device: Devices used to transmit or receive data in a digital form.

Tilt angle: A fixed angle measured from the horizontal to which a solar array is tilted. The tilt angle is chosen to maximize the array output. Depending upon latitude, season and time of day this angle will vary.

Tracking array: An array that is mounted on a movable structure that attempts follow the path of the sun. Some tracking arrays are single axis while others are dual.

Voltage: A measure of the force or "push" given the electrons in an electrical circuit; a measure of electrical potential. One volt produces one amp of current when acting against a resistance of one ohm.

Watt: Unit of power. Power is the rate of using energy to do work.

Additional items of interest:

mechanical: 746 watts = 1 horsepower

electrical: one watt is the power developed or

dissipated in one volt circuit

(see volt) in which a current of one ampere (6

1/4 million electrons per second) is flowing.

Watts = amps x volts.

Thermal: 1 watt = about 14.3 calories of heat

energy per minute. =3.413 BTU per hour =1 joule/sec.

Examples: typical 4" silicon cell produces about 1 watt at peak (noontime sunlight). One 1.3m fluorescent tube used 40 watts. One watt will heat announce of water from the freezing point to the boiling point in a little over 3hours. The sun delivers (at peak) about 100 watts 30sqcm of surface normally.

Solar Energy

based on web page by Ken CromptonPhotovoltaic Systems

Movement of Light

Solar Cell Materials

Turning Sunlight into Energy

From Cells to Arrays

Cells to Arrays - a closer look

PV Cells with Battery Storage

How does a cell produce electricity?

Glossary of PV Terms

Photovoltaic (or PV) systems convert light energy into electricity. The term "photo" is a stem from the Greek "phos," which means "light." "Volt"is named for Alessandro Volta (1745-1827), a pioneer in the study of electricity. "Photo-voltaics," then, could literally mean "light-electricity. Most commonly known as "solar cells," PV systems are already animportant part of our lives. The simplest systems power many of the small calculators and wrist watches we use every day. More complicated systems provide electricity for pumping water, powering communications equipment, and even lighting our homes and running our appliances. In asurprising number of cases, PV power is the cheapest form of electricity for performing these tasks.

Here, we describe the PV effect that allows various materials to produce electricity from sunlight; show how PV cells, modules, and arrays are made; explain why PV is the most logical power choice in many different cases; and provide real examples of how this science is improving the lives of people all over the world!

Movement of Light

The movement of light from one location to another can best be describedas though it were a wave, and different types of radiation are characterizedby their individual wavelengths (a wavelength is the distance from the peakof one wave to the peak of the next). These wavelengths indicate radiationwith different amounts of energy; the longer the wavelength, the less the energy. Red light, then, has a longer wavelength and thus has less energythan violet light.

Each second, the sun releases an enormous amount of radiant energy intothe solar system. The Earth receives a tiny fraction of this energy; still, anaverage of 1367 watts (W) reaches each square meter (m2) of the outeredge of the Earth's atmosphere. The atmosphere absorbs and reflects some of this radiation, including most X-rays and ultraviolet rays. Still, the amount of sunshine energy that hits the surface of the Earth every minute is greater than the total amount of energy that the world's human population consumes.

The Earth's atmosphere and cloud cover absorb, reflect, and scatter someof the solar radiation entering the atmosphere.Nonetheless, enormous amounts of direct diffuse sunshine energy reach the Earth's surfaceand

can therefore be used to produce photovoltaic electricity.

Solar Cell Materialscan therefore be used to produce photovoltaic electricity.

The most important parts of a solar cell are the semiconductor layers, because this is where the electron current is created. There are a number of different materials suitable for making these semiconducting layers, and each has benefits and drawbacks. Unfortunately, there is no one ideal material for all types of cells and applications. In addition to the semiconducting materials, solar cells consist of a top metallic grid or other electrical contact to collect electrons from the semiconductor and transfer them to the external load, and a back contactlayer to complete the electrical circuit. Then, on top of the complete cell is typically a glass cover or other type of transparent encapsulant to seal the cell and keep weather out, and an anti reflective coating to keep the cell from reflecting the light back away from the cell.

A typical solar cell consists of a cover glass or other encapsulant, an anti-reflective layer, a front contact to allow the electrons to enter a circuit and a back contact to

allow them to complete thecircuit, and the semiconductor layers where the electrons begin and complete their voyages.

Here are some substances commonly used in solar cells:

Silicon

Silicon is still the most popular solar cell material for commercial applications because it is so readily abundant (it is actually the second most abundant element in the Earth's crust second only to oxygen!). However, to be useful in solar cells, it must be refined to 99.9999% purity.

In single-crystal silicon, the molecular structure of the material is uniform because the entire structure is grown from the same or a "single" crystal. This uniformity is ideal for efficiently transferring electrons through the material. To make an effective PV cell, silicon is "doped" to make it n-type and p-type. Semicrystalline silicon, on the other hand, consists of several smaller crystals or "grains," which introduce "boundaries." These boundaries impede the flow of electrons and encourage them to recombine with holes and thereby reduce the power output of the cell. However, semicrystalline silicon is much cheaper to produce than single-crystalline silicon, so researchers are working on other ways of minimizing the effects of grain boundaries.

Gallium Arsenide

Gallium arsenide (GaAs) is a compound semiconductor: a mixture of two elements, gallium (Ga) and arsenic (As). Gallium is a byproduct of the smelting of other metals, notably aluminum and zinc, and it is rarer than gold. Arsenic is not rare, but it is poisonous. Gallium arsenide's use in solar cells has been developing synergistically with its use in light-emitting diodes, lasers, and other opto-electronic devices.

GaAs is especially suitable for use in multijunction and high-efficiency solar cells for several reasons:

1. The GaAs band gap is 1.43 eV, nearly ideal for single-junction solar cells.

2. GaAs has an absorbtivity so high it requires a cell only a few microns thick to absorb sunlight. (Crystalline silicon requires a layer 100 microns or more in thickness.)

3. Unlike silicon cells, GaAs cells are relatively insensitive to heat. (Cell temperatures can often be quite high, especially in concentrator applications.)

4. Alloys made from GaAs using aluminum, phosphorus, antimony, or indium have characteristics complementary to those of gallium arsenide, allowing great flexibility in cell design.

5. GaAs is very resistant to radiation damage. This, along with its high efficiency, makes GaAs very desirable for space applications.

One of the greatest advantages of gallium arsenide and its alloys as PV cell materials is the wide range of design options possible. A cell with a GaAs base can have several layers of slightly different compositions that allow a cell designer to precisely control the generation and collection of electrons and holes. (To accomplish the same thing, silicon cells have been limited to variations in the level of doping.) This degree of control allows cell designers to push efficiencies closer and closer to theoretical levels. For example, one of the most common GaAs cell structures uses a very thin window layer of aluminum gallium arsenide. This thin layer allows electrons and holes to be created close to the electric field at the junction.

Polycrystalline Thin Films

One of the scientific discoveries of the computer semiconductor industry that has shown great potential for the PV industry is thin film technology. Polycrystalline thin film devices require very little semiconductor material and have the added advantage of being easy to manufacture. Rather than growing, slicing, and treating a crystalline ingot (required for single-crystal silicon), we sequentially deposit thin layers of the required materials.

Several different deposition techniques are available, and all of them are potentially cheaper than the ingot growth techniques required for crystalline silicon. Best of all, these deposition processes can be scaled uneasily so that the same technique used to make a 2-inch x 2-inch laboratory cell can be used to make a 2-foot x 5-foot module (in a sense, a huge cell!). Like amorphous silicon, the layers can be deposited on various low-cost substrates (actually "superstrates," see Transparent Conductors)

like glass or plastic in virtually any shape -- even flexible plastic sheets.

Single-crystal cells have to be individually interconnected into a module, but thin film devices can be made monolithically (as a single unit). Layer upon layer is deposited sequentially on a glass superstrate, from the antireflection coating and conducting oxide, to the semiconductor materialand the back electrical contacts.

Polycrystalline Thin Films:

Cell Structure

Unlike most single-crystal cells, the typical thin film device does not use a metal grid for the top electrical contact. Instead, it uses a thin layer of a transparent conducting oxide (such as tin oxide). These oxides are highly transparent and conduct electricity very well. A separate antireflection coating may be used to top off the device, or the transparent conducting oxide may serve this function as well.

Polycrystalline thin film cells comprise many tiny crystalline grains of semiconductor materials. The materials used in polycrystalline thin-film cells have properties that are different from those of silicon, so it has proven to be better to create the electric field with an interface between two different semiconductor materials. This type of interface is called a heterojunction ("hetero" because it is formed from two different materials,

in comparison to the "homojunction" formed by two doped layers of the same material, such as the one in silicon solar cells).

Turning Sunlight into Energy

About Conversion Efficiencies

The conversion efficiency of a PV cell is the proportion of sunlight energythat the cell converts to electrical energy. This is very important whendiscussing PV devices, because improving this efficiency is vital to makingPV energy competitive with more traditional sources of energy (e.g., fossilfuels). Naturally, if one efficient solar panel can provide as much energy as two less efficient panels, then the cost of that energy (not to mention the space required) will be reduced. For comparison, the earliest PV devicesconverted about 1%-2% of sunlight energy into electric energy. Today'sPV devices convert 7%-17% of light energy into electric energy.Of course, the other side of the equation is the money it costs to manufacture the PV devices. This has been improved over the years aswell. In fact, today's PV systems produce electricity at a fraction of thecost of early PV systems.

AC and DC Current

PV modules, because of their electrical properties, produce direct ratherthan alternating current (ac). Direct current (dc) is electric current thatflows in a single direction. Many simple devices, such as those that run onbatteries, use direct current. Alternating current, in contrast, is electriccurrent that reverses its flow direction at regular intervals. This is the typeof electricity provided by utilities and is required to run most modern appliances and electronic devices.

In the simplest systems, dc current produced by PV modules is useddirectly. In applications where ac current is necessary, an inverter can beadded to the system to convert the dc current to ac current.

Turning Sunlight Into Electricity

Light and the Sun

The sun's energy is vital to life on Earth. It determines the Earth's surfacetemperature and supplies virtually all the energy that drives natural globalsystems and cycles. Although some other stars are enormous sources ofenergy in the form of X-rays and radio signals, our sun releases 95% of itsenergy as visible light. Yet, visible light represents only a fraction of thetotal radiation spectrum; infrared and ultraviolet rays are also significantparts of the solar spectrum.

frequency and the greater the

energy (expressed in eV, or electron volts).

Each portion of the solar spectrum is associated with a different level ofenergy. Within the visible portion of the spectrum, for example, red light isat the low-energy end and violet light is at the high-energy end (having halfagain as much energy as red light). In the invisible portions of thespectrum, photons in the ultraviolet region, which cause the skin to tan,have more energy than those in the visible region. Likewise, photons in theinfrared region, which we feel as heat, have less energy than the photonsin the visible region.

The "photovoltaic effect" is the basic physical process through which a PVcell converts sunlight into electricity. Sunlight is composed of photons, orparticles of solar energy. These photons contain various amounts ofenergy corresponding to the different wavelengths of the solar spectrum (see "Light and the Sun" for more about that). When photons strike a PVcell, they may be reflected or absorbed, or they may pass right through.

Only the absorbed photons generate electricity. When this happens, theenergy of the photon is transferred to an electron in an atom of the cell(which is actually a semiconductor). With its newfound energy, the electron is able to escape from its normal position associated with thatatom to become part of the current in an electrical circuit. By leaving thisposition, the electron causes a "hole" to form. Special electrical propertiesof the PV cell-a built-in electric field provide the voltage needed to drive

the current through an external load (such as a light bulb).

p-Types, n-Types, and the Electric Field

To induce the electric field within a PV cell, two separate semiconductorsare sandwiched together. The "p" and "n" types of semiconductorscorrespond to "positive" and "negative" because of their abundance ofholes or electrons (the extra electrons make an "n" type because an electron actually has a negative charge).

Although both materials are electrically neutral, n-type silicon has excess electrons and p-type silicon has excess holes. Sandwiching these togethercreates a p/n junction at their interface, thereby creating an electric field. When the p-type and n-type semiconductors are sandwiched together, theexcess electrons in the n-type material flow to the p-type, and the holes

thereby vacated during this process flow to the n-type. (The concept of a hole moving is somewhat like looking at a bubble in a liquid. Although it's the liquid that is actually moving, it'seasier to describe the motion of thebubble as it moves in the opposite direction.) Through this electron andhole flow, the two semiconductors act as a battery, creating an electricfield at the surface where they meet (known as the "junction"). It's this

field that causes the electrons to jump from the semiconductor out toward the surface and make them available for the electrical circuit. At this sametime, the holes move in the opposite direction, toward the positive surface, where they await incoming electrons.

From Cells to Arrays

The PV cell is the basic unit in a PV system. An individual PV cell typicallyproduces between 1 and 2 watts, hardly enough power for the greatmajority of applications. But we can increase the power by connectingcells together to form larger units called modules. Modules, in turn, can beconnected to form even larger units known as arrays, which can be interconnected for more power, and so on. In this way, we can build a PVsystem to meet almost any power need, no matter how small or great.

Modules or arrays, by themselves, do not constitute a PV system. We must also have structures on which to put them and point them toward thesun, and components that take the direct current (dc) electricity producedby the modules or arrays and condition the electricity so it can be used inthe specific application. These structures and components are referred toas the balance of system (BOS).

When sunlight strikes a solar cell, only certain bands (or wavelengths)of light will cause electrons to move within the semiconductor, therebyproducing electric current. The energy "band gap" of thesemiconductor determines the ideal portion of the light spectrum that will create this effect. To allow it all to happen, the semiconductorlayers must be constructed so as to produce an electric fieldThe wavelengths of light above the cell's band gap (left) carry more energy. Some of this energy is absorbed to free electrons in the cell,and some of it is absorbed as heat. Light energy below the cell's band gap

(right) passes right through the field without affecting electron movement. Overall, only abut 55% of the sun's light energycan be converted into electricity.

So, the typical solar cell receives the entire solar spectrum. But onlythe light energy above the cell's energy gap

will cause electrons to move and become part of an electric circuit.

Cells to Arrays

The solar cell is the basic building block of a PV system. Individual cells can vary in size from about 1 cm (1/2 in.) to about 10 cm (4 in.) across. However, one cell only produces 1-2 W, which isn't enough power for most applications

(Photo: Siemens Solar Industries)

A module typically consists of several solar cells, although thin-film materials like amorphous silicon and cadmium

telluride can be made directly into modules, effectively bypassing the solar cell. These two silicon modules are rated at approximately 50 W each and provide power for a street light using 12 V battery storage.

Modules such as these can also be connected into arrays for more power.

(Photo: W. Gretz, NREL)

Arrays are the large power producers and consist of several modules. They can be used to provide up to several megawatts of electric power.

The basic photovoltaic cell typically produces only a small amount of power. To produce more power, cells can be interconnected to form modules, which can in turn be connected into arrays to produce yet more power. Because of this modularity, PV systems may be designed to meet any electrical requirement, no matter how large or how small.

PV Cells with Battery Storage

PV systems with batteries operate by connecting the PV modules to abattery, and the battery, in turn, to the load. During daylight hours, the PVmodules charge the battery. The battery supplies power to the loadwhenever needed. A simple electrical device called a charge controllerkeeps the batteries charged properly and helps prolong their life by protecting them from overcharging or from being completely drained. Batteries make PV systems useful in more situations, but also require somemaintenance. The batteries used in PV systems are often similar to carbatteries, but are built somewhat differently to allow more of their storedenergy to be used each day. (They are said to be "deep cycling," like thebatteries used on golf carts.) Batteries designed for PV projects pose thesame risks and demand the same caution in handling and storage as automotive batteries. The fluid in unsealed batteries should be checkedperiodically, and batteries should be protected from extremely cold weather.

A solar generating system with batteries supplies electricity when it isneeded. How much electricity can be used after sunset or on cloudy daysis determined by the output of the PV modules and the nature of thebattery bank. Including more modules and batteries increases system cost, so energy usage is carefully studied to determine optimum system size. Awell designed system balances cost and convenience to meet the user'sneeds, and can be expanded if those needs change.

How does a cell produce electricity?

A typical solar cell is made from a substance called silicon. Silicon is known as a semiconductor. A semiconductor is neither a good insulator nor a good insulator; it falls somewhere in between. A solar cell is constructed with silicon that has been altered to form two different types of semiconductor material. These two different types of silicon are then joined in such a way as to form a junction.

Due to the different types of semiconductor material that make up this junction, a permanent electric field is forced to appear in this region. When a photon from a light source such as the sun strikes the cell, it causes an electron in the semiconductor material to jump to a higher orbit and jump from atom to atom. The permanent electric field forces the electron to move only in a particular direction, out of the cell and through a circuit such as a light bulb, a motor or battery etc. and then back to the other side of the junction thus performing work.

By connecting cells together to form a solar panel we can do even more work. The typical individual silicon solar cell has the potential of generating about half a volt, but by wiring them in series or end to end you can increase the voltage. In other words, 36 individual cell will produce about 18 volts. The size of the individual cell is what determines the amount of current of amps that a solar panel can produce.

Glossary of PV Terms

This brief glossary is offered as a basic guideline. Click on any term to receive the definition, then click on the term again to return here.

AC

Ampere

Ampere Hour

Ampere Hour Meter

Angle Of Incidence

Array

Balance Of System

Battery

Battery Capacity

Battery Cell

Battery Available Capacity

Battery Energy Capacity

Battery Cycle Life

Battery Life

Blocking Diode

Cathodic Protection

Cell (Battery)

Cell (Solar)

Charge Rate

Charge Controller

Concentrator

DC

Depth Of Discharge

Diffuse Insolation

Direct Insolation

Efficiency

Electrolyte

Electric Current

Electricity Energy

Electrons

Equalization

Equalizing Charge

Float Service

Full Sun

Gassing

Grid

Grid Lines

Hermetic Seal

Hybrid System

Incident Light

Insolation

Inverter

Kilowatt-Hour (Comparison Of Fuel Equivalents)

Load

Maximum Power

Module

Open Circuit Voltage

Panel

Parallel Connection

Peak Power Point

Peak Watts

Photon

Photovoltaic Cell

Photovoltaic Effect

Photovoltaic System

Power Conditioner

Power Factor

Regulator

Renewable Energy

Semiconductor

Series Connection

Silicon

Single-Crystal Structure

Solar Cell

Solar Panel

Stand-Alone System

Storage Battery

Sulfation

Telemetry Device

Tilt Angle

Tracking Array

Voltage

Watt

AC: Alternating Current. Direction of current reverses periodically, usually many times per second. Electricity transmission networks use AC because voltage can be controlled with relative ease.

Ampere (amp): A unit of electrical current or rate of flow of electrons. One volt across one ohm of resistance causes a current flow of one ampere. One ampere is equal to 6.235 x 1018 electrons per second passing a given point in a circuit.

Ampere hour: (amp hr. Or ah), a measure of current overtime, used to measure battery capacity.

Ampere hour meter: An instrument that monitors current

with time. The indication is the product of current (in amperes) and time (in hours).

Angle of Incidence: The angle between the direct solar beam and the normal (90 degrees) to the active surface (degrees).

Array: Any number of photovoltaic modules connected together electrically to provide a single electrical output. An array is a mechanically integrated assembly of modules or panels together with support structure (including foundation and other components, as required) to form a free- standing field installed unit that produces DC power.

Balance of systems (bos): Parts or components of a photovoltaic system other than the photovoltaic array.

Battery: Two or more electrochemical cells enclosed in

a container and electrically interconnected in an appropriate series/parallel arrangement to provide the required operating voltage and current levels. Under common usage, the term battery also applies to a single cell if it constitutes the entire

electrochemical storage system.

Battery capacity: The maximum total electrical charge,expressed in ampere-hours (ah), that a battery can deliver to a load under a specific set of conditions.

Battery cell: The simplest operating unit in a storage

battery. It consists of one or more positive electrodes or plates, an electrolyte that permits ionic conduction, one or more negative electrodes or plates, separators between plates of opposite polarity, and a container for all the above.

Battery available capacity: The total maximum charge, expressed in ampere-hours, that can be withdrawn from a cell or battery under a specific set of operating conditions including discharge rate, temperature, initial state of charge, age, and cutoff voltage.

Battery energy capacity: the total energy available, expressed in watt-hours (kilowatt-hours), that can be withdrawn from a fully-charged cell or battery. The energy capacity of a given cell varies with temperature, rate, age, and cutoff voltage.

This term is more common to system designers than it is to the battery industry where capacity usually refers to ampere-hours..

Battery cycle life: The number of cycles, to a specified depth of discharge, that a cell or battery can undergo before failing to meet its specified capacity or efficiency performance criteria..

Battery life: The period during which a cell or battery

is capable of operating above a specified capacity or efficiency performance level. For example, with lead-acid batteries, end-of- life is generally taken as the point in time when a fully charged cell can deliver only 80% of its rated capacity. Beyond this state of aging, deterioration and loss of capacity begins to accelerate rapidly. Life may be measured in cycles and/or years, depending on the type of service for which the cell or battery is intended.

Blocking diode: A semiconductor connected in series

with a solar cell or cells and a storage battery to keep the battery from discharging through the cell when there is no output, or low output, from the solar cell. It can be thought of as a one-way valve that allows electrons to flow forwards, but not backwards.

Cathodic protection: Systems that protect underground

metal from corrosion by running small electrical currents along the metal. Most often used to protect wellheads, oil, gas, and water pipelines.

Cell (battery): A single unit of an electrochemical device capable of producing direct voltage by converting chemical energy into electrical energy. A battery usually consists of several cells electrically connected together to produce higher voltages. (sometimes the terms cell and battery are used interchangeably).

Cell (solar): The smallest, basic photovoltaic device that generates electricity when exposed to light.

Charge rate: The current applied to a cell or battery to restore its available capacity. This rate is commonly normalized by a charge control device with respect to the rated capacity of the cell or battery.

Charge controller: a component of photovoltaic system that controls the flow of current to and from the battery to protect the batteries from over-charge and over-discharge. The charge controller may also indicate the system operational status.

Concentrator: a photovoltaic module which includes optical components, such as lenses, to direct and concentrate sunlight onto a solar cell of smaller area. Most concentrator arrays must directly face or track the sun.

DC: Direct Current. A one way flow of electric current. Typical sources of direct currents are electric cells, rectified power units and direct current generators. This is the current flow produced by a solar cell system. To be used for typical 120 volt or 220 volt household appliances, it must be converted to AC.

Depth of Discharge (dod): The ampere-hours removed from a fully charged cell or battery, expressed as a percentage of rated capacity. For example, the removal of 25 ampere- hours from a fully charged 100 ampere-hours rated cell results in a 25% depth of discharge. Under certain conditions, such as discharge rates lower than that used to rate the cell, depth of discharge can exceed 100%.

Diffuse insolation: The radiant energy from the sky incident upon unit surface area during a specified time period (same units as for direct insolation).

Direct insolation: The radiant energy from the sun (and a small area of sky surrounding it, defined by the acceptance angle of the pyrheliometer) incident upon unit surface area during a specified time period. (mj/m2 per hour, day, week, month or year, as the case may be).

Efficiency: The ratio of power output of a photovoltaic cell to the incident power from the sun or simulated sun sources under specified standard insolation conditions.

Electrolyte: The fluid used in batteries as the transport medium for positively and negatively charged ions.

Electric current: The rate at which electricity flows

through an electrical conductor, usually measured in amperes (amps).

Electricity energy: Resulting from the flow of charge particles, such as electrons ions.

Electrons: A negatively charged particle. The movement of electrons in an electrical conductor constitutes an electric current.